In the most basic of definitions, blade offset is the distance from the tip of the blade to the center of its shaft.

It’s also a measurement of the blade’s effective cutting width. The blade offset value is used in calculating the distance the blade must travel past a corner in order for the tip of the blade to reach the same point when its direction changes. This is most visible when cutting squares. If blade offset is set too low, corners will be rounded. If blade offset is set too high, your corners will bulge outwards.

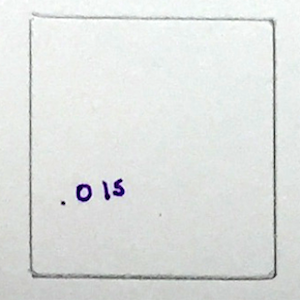

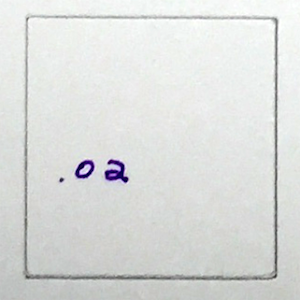

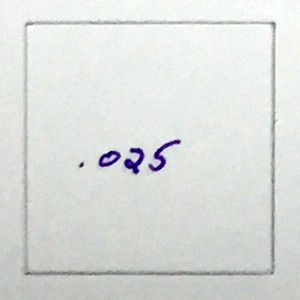

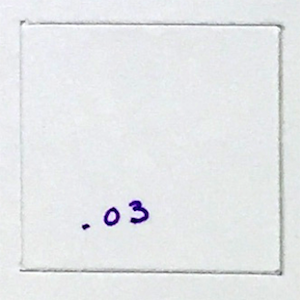

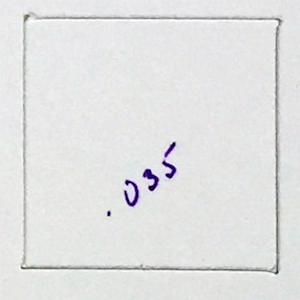

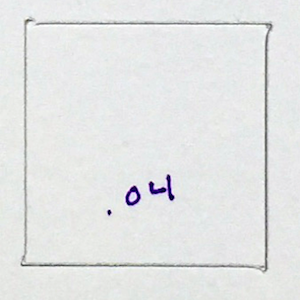

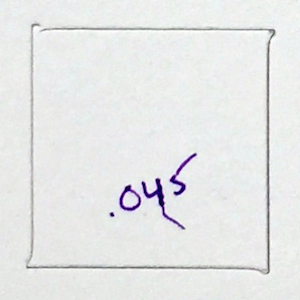

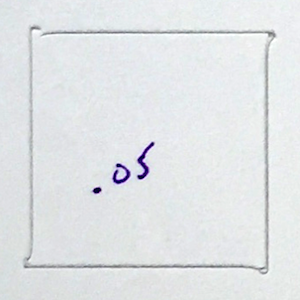

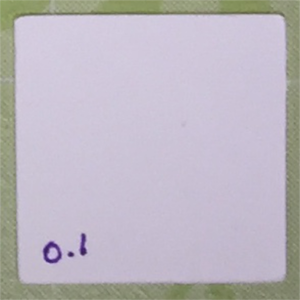

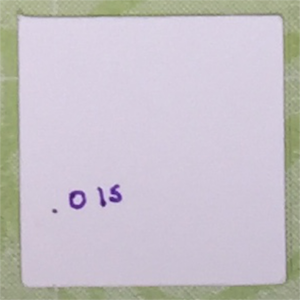

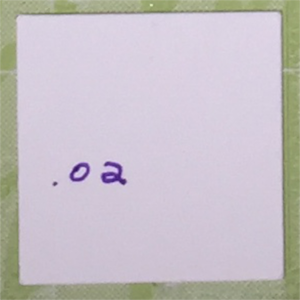

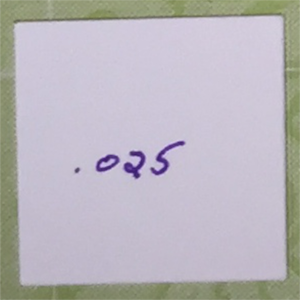

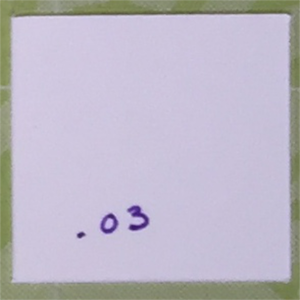

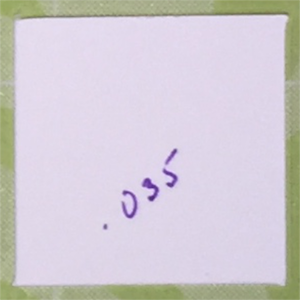

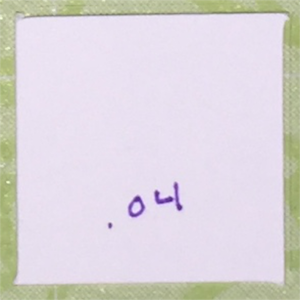

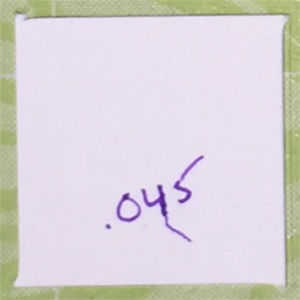

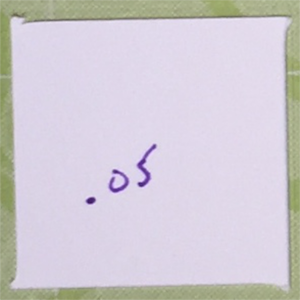

For most applications, there is sufficient leeway in blade offset so that a slightly imprecise value will still yield an acceptable cut. The examples below are provided to illustrate a range of values and the effects they yield on a simple 1″ square.

As we can see above, the corners are slightly rounded until we get to 0.015″. At 0.020″-0.025″, it appears we’re at an ideal square. At 0.03″, the corners start turning outwards and by 0.05″ we start to see a pinwheel effect.

Now, this is all well and good, but let’s take a look at the remaining squares after the paper has been removed.

Unless I were doing very critical work, I wouldn’t be upset with any of the results until a blade offset of 0.035″ is reached. The corners are clearly beginning to protrude and my personal preference would be for an ever-so-slightly rounded circle rather than one with tails.

I hope viewing the results of this test helps to shed some light on this particular setting and the effects of different blade offset values. Thanks for reading!

Comments

Maybe it’s just me, but it seems that the .035 has serif like corners. In face, the cleanest cuts appear to be with .02 and .025. I can’t tell what the .03 image looks like, it’s too small. I’ve always used .01, as I thought that was the recommended setting.

Yep, I left mine at .025. .035 is where it starts getting obviously worse.

You can duplicate the same test with your blade, if you’re not getting the best corner cuts. Another user found their best setting was .015 rather than .01. I had no issue with .01 until I scrutinized things and saw that .02/.025 was marginally better, but I tend to cut more rounded things than angled.

I have been, unsuccessfully, trying to cut 2″ snowflakes out of 36 gauge copper tooling foil. Have tried both red and blue blades (discovered that I have a faulty blue blade holder) and different cutting depths/speeds to no avail. I will be attending the michigan retreat in october and plan on bringing some of the copper along to let you have a go at it. Had my heart set on being able to cut these on the force.

Was this with the blue blade(Thick) or the red blade (Standard)?

Red blade!